Mercedes-Benz Automotive Upgrading Project at Shunyi Production Base

Active Harmonic Filters selected to protect power quality for a Factory 56–standard NEV production base

- Industry: Automotive manufacturing (high-end NEV)

- Facility: Beijing Benz Shunyi Plant (benchmarking Daimler “Factory 56”)

- Scale: ~1.06 million m² | Total investment RMB 11.9 billion

- Selected solution: Low-Voltage Active Harmonic Filter (AHF/APF)

Project Context:

The Beijing Benz Shunyi Base Upgrade & Expansion Project is positioned as a high-end new energy vehicle production base built to the benchmark logic of Daimler’s Factory 56. The site covers approximately 1.06 million square meters with a total investment of RMB 11.9 billion, integrating advanced production processes and large-scale automation.

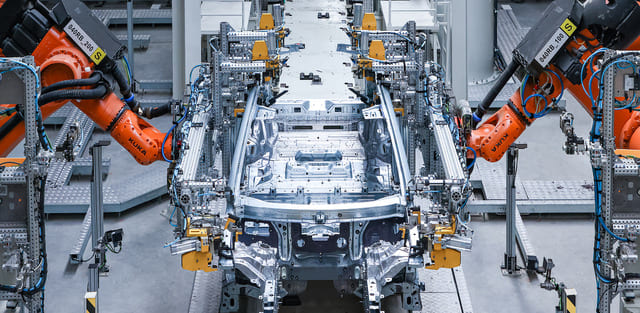

This is not a conventional automotive plant retrofit. The factory is designed around high-density automation—including automated servo press lines, extensive robotic welding and assembly, and intelligent production systems aimed at high flexibility and high throughput. Public coverage references ~1,400 KUKA robots, along with advanced joining and inspection approaches such as 3D laser scanning welding and Best Fit intelligent jointing, with an automation rate reaching roughly 90%

Harmonic Risks in Automotive Manufacturing

In highly automated vehicle manufacturing, power quality is a production variable. A modern body shop and press shop combine large numbers of electronically controlled drives and precision control systems; when the electrical environment becomes unstable, the penalty is rarely “slightly lower efficiency.” The real risk is line interruptions, equipment protection actions, and recovery work that consumes time, capacity, and manpower

The financial exposure can be severe. Industry studies have reported that even a short voltage sag–driven stoppage in an automotive plant can lead to losses on the order of hundreds of thousands of US dollars, driven by shutdown impact and the rework/restart cycle. In a benchmark factory designed for high throughput and tight quality control, the practical objective becomes clear: reduce the electrical triggers that cause nuisance events, stress distribution assets, or compromise stable continuous production.

Power Quality Stress Profile

In projects of this class, the dominant stressors are consistent—and Shunyi amplifies them due to automation density and the concentration of high-powered production equipment:

-

High harmonic pressure from automation-heavy lines: robots, weld systems, and digitally controlled production equipment introduce non-linear current draw that accumulates at the distribution level.

-

Voltage fluctuation and flicker exposure: fast-changing, intermittent loads (especially body shop and press processes) can create visible electrical instability if not managed correctly.

-

Low power factor tendencies under variable operating states: motor-driven systems and mixed production modes can pull reactive power in ways that change by shift, model mix, and line state.

-

Three-phase imbalance risk in complex plants: uneven single-phase and distributed auxiliary loads can create imbalance that affects equipment stability and increases losses.

-

“Benchmark factory” sensitivity: with 90%+ automation and strong digital integration, the tolerance for electrical disturbances is lower—because upstream issues can propagate faster through interconnected systems.

This is why power-quality governance in advanced auto plants must be designed as plant infrastructure, not as a patchwork fix.

What we delivered

After competitive bidding and technical evaluation, the project selected our BLUEWAVE Low-Voltage Active Harmonic Filter (AHF/APF) as the core mitigation measure to protect the power supply system. The solution focus was straightforward: reduce harmonic burden, stabilize electrical behavior under changing production states, and protect the distribution system feeding mission-critical production lines.

How our AHF addressed the project’s needs

-

Real-time harmonic mitigation: continuously detects distortion and injects compensation current to reduce harmonic stress on upstream transformers, feeders, and low-voltage distribution equipment.

-

Fast dynamic response for changing loads: designed to track rapid operating transitions typical of robotics and automated manufacturing—helping prevent disturbances from becoming repeated events.

-

Reactive power support to improve power factor: provides reactive compensation in coordination with harmonic filtering to reduce avoidable capacity drag and support steadier operation.

-

Site-fit deployment flexibility: supports practical installation constraints (CT placement options, configurable operating priority) so mitigation fits real wiring and operating goals—without forcing redesign of the distribution system.

-

Scalable cabinet architecture: supports phased deployment and capacity expansion as production lines ramp or change.

Results and Benefits

After implementation, the operator gained a cleaner, more stable LV power baseline suited to high-automation manufacturing: reduced harmonic impact on the supply system, lower distribution stress that accumulates into heat and maintenance issues, and improved operating stability for production lines that have little tolerance for nuisance events. In practical terms, the value is fewer avoidable electrical disruptions, more predictable line operation, and a stronger reliability margin for a benchmark NEV facility built for high throughput and future expansion.

Power Quality Solutions Proven in Automotive Manufacturing

Cleaner power for welding lines, press shops, and high-drive utility systems—without disrupting production.

Let's talk about your project

Contact us to discuss your loads, harmonic profile, and reliability requirements. We’ll recommend a practical active filtering approach that fits your electrical system.