Linglong Tire 110kV Substation Project

High-Voltage Reactive Power Compensation to Stabilize Plant Power Quality for Large-Scale Tire Manufacturing

- Project type: Dedicated, self-built 110kV user substation

- Primary objectives: Reactive power compensation, power factor improvement, harmonic risk control, and stable supply quality

- Solution deployed: High-Voltage Automatic Reactive Power Compensation Unit (staged capacitor-bank switching with protection + monitoring)

Project Context:

Linglong Tire built a dedicated 110kV substation to supply its production base with a stable internal power system capable of supporting large-scale lines and continuous operation. Unlike ordinary factory supply arrangements, a 110kV owner-operated substation places the responsibility for power quality stability, equipment protection, and switching reliability directly on the plant’s own power infrastructure—because any disturbance affects the entire production footprint, not just one workshop.

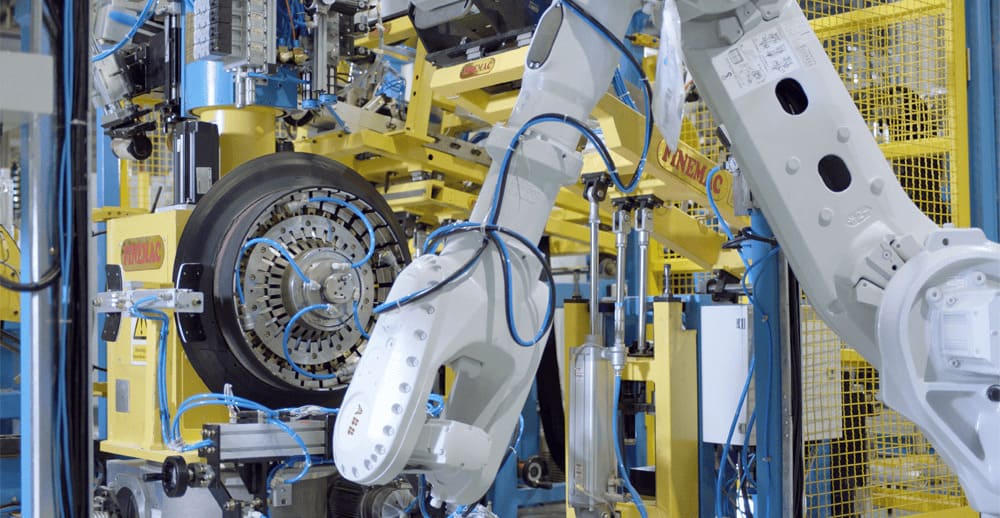

In a tire plant, the electrical profile is typically dominated by large induction motors and drive-controlled equipment supporting mixing, conveying, extrusion, calendaring, curing, compressed air, cooling, and auxiliary systems. The result is a predictable set of high-stakes operational pressures:

-

Reactive power demand is continuous and load-dependent, which can pull power factor down and increase current throughout the plant network.

-

Load steps are frequent as production states change, requiring compensation that reacts reliably—not “manually once per shift.”

-

Harmonics are a practical constraint in modern manufacturing sites because variable-speed drives and power electronics are widely used; this increases the need for equipment that can operate safely in a harmonic environment and avoid protection mis-operations.

-

The cost of instability is real: higher losses and heating, reduced effective capacity, accelerated equipment aging, nuisance trips, and production interruptions that cascade into downtime, scrap risk, and maintenance escalation.

Why power quality mattered here — and what was at stake

In this large industrial plants, power quality challenges most commonly present as:

-

Low or fluctuating power factor driven by motor-heavy loads and changing operating states

-

Higher current and thermal stress on transformers, cables, and switchgear when reactive current is not controlled

-

Switching sensitivity (frequent compensation operations required to keep the system within target)

-

Harmonic exposure from widespread power-electronics loads, which places practical constraints on capacitor-bank operation and protection coordination

What made this project distinctive was the combination of:

-

A dedicated 110kV substation serving large-scale production—meaning reliability expectations are exceptionally high and the plant cannot rely on “external buffering” to smooth out internal issues

-

The need for automatic, repeatable reactive control that can track production-state variation without manual intervention

-

A requirement for protection depth and fail-safe behavior, because any fault or mis-operation at HV compensation level can have an outsized effect on plant continuity

What we delivered

For this project, our solution and products were selected after competitive bidding and technical evaluation to provide automatic, staged reactive power compensation while supporting stable operation in an environment where harmonics and load fluctuation must be expected.

How it works (clear, project-relevant)

-

Our product performs closed-loop reactive power control using a strategic algorithm.

-

It switches capacitor banks in stages via high-voltage vacuum contactors.

-

When reactive power drops below the set threshold, the controller automatically issues switching commands to connect the required number of capacitor steps.

-

When reactive power rises above the set value, it disconnects capacitor steps accordingly.

-

The entire process is fully automatic, supporting stable power factor behavior as production loads change.

Why this design fits a 110kV owner substation

Our solution is engineered not just for compensation performance, but for real-world endurance and protection in high-voltage plant distribution:

-

Operating margin for voltage and harmonic conditions: designed for long-term operation under 1.1 Un steady-state overvoltage; total voltage peak including harmonic components is controlled within defined limits (per spec).

-

Overcurrent tolerance under harmonics/overvoltage: supports steady-state current up to 1.3 In RMS, with allowable higher current under maximum capacitance deviation (per spec).

-

Capacitor protection architecture: internal + external fuse protection options; supports unbalance protection methods such as open-delta voltage / differential / neutral unbalance current, plus over/undervoltage and overcurrent protections.

-

Switching reliability: capacitor switching vacuum contactors designed for frequent operation, fast response, low restrike probability, and low maintenance—important when compensation needs to track load changes repeatedly.

-

Selective fault handling: dedicated digital protection and monitoring enables staged overcurrent/zero-sequence protection; faults isolate the affected bank while others continue operating.

-

Integration readiness: RS485 port supports remote communication and monitoring.

Results and Benefits

By stabilizing reactive power behavior at the substation level, our solution helps the plant maintain a healthier power factor and a more stable electrical baseline across shifting production states. That translates into lower electrical losses, reduced stress on power equipment, improved utilization of system capacity, and fewer power-quality-related interruptions that can disrupt high-throughput manufacturing. With robust switching and protection built for high-voltage capacitor applications, the system supports safer, more predictable substation operation under real industrial conditions—including environments where harmonics are present.

Trusted Power Quality Partner for Tire Manufacturing Plants

Power quality improvements that protect uptime, equipment health, and energy performance

Let's talk about your project

Contact us to discuss your loads, harmonic profile, and reliability requirements. We’ll recommend a practical active filtering approach that fits your electrical system.