GAC R&D Center Phase II

Power Quality Stabilization for Precision R&D Labs and Advanced Test Equipment

- Industry: Automotive R&D / Testing & Validation

- Project type: R&D center expansion (Phase II construction)

- Key issue: Harmonics + three-phase current imbalance disrupting precision instruments and power electronics

- Solution deployed: Hybrid Dynamic Filter Compensation System

Project Context:

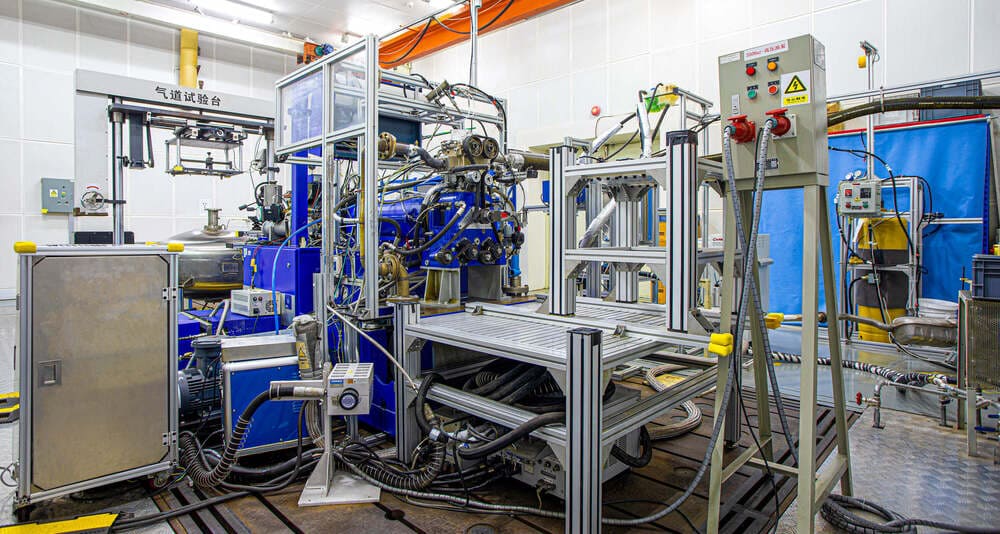

The GAC R&D Center is responsible for new-product and new-technology development planning across the group and executes specialized R&D programs through 15 technical departments—covering vehicle integration, powertrain, electronics & electrical systems, simulation, NVH, prototype build, and full-spectrum testing.

Unlike a conventional factory, this environment concentrates precision instruments and computer-/microprocessor-controlled equipment. These devices depend on a clean, stable electrical supply; when power quality deteriorates, the impact is immediate: test integrity, data reliability, and lab productivity are all at risk.

-

Harmonic-rich nonlinear loads

Power supplies, servo drives, inverters, laboratory equipment, chargers, and power electronics test benches can generate harmonic currents that distort the voltage seen by other devices. In practice, this often correlates with “mysterious” malfunctions in sensitive equipment—especially when multiple devices share the same feeders. -

Three-phase current imbalance

R&D campuses often expand area-by-area. As single-phase and unevenly distributed loads accumulate, phase loading becomes asymmetric. This can drive neutral current increase, abnormal heating, and instability for equipment expecting balanced three-phase conditions. -

Fast-changing reactive power demand

Test rigs and large electromechanical systems switch states frequently. That creates rapid swings in reactive power and power factor—conditions that conventional static solutions struggle to follow, especially when the site runs a mix of precision electronics and heavy test equipment.

Unique to this project: the most visible pain wasn’t abstract “THD”—it was frequent, operator-facing symptoms: data errors, blurred images, information loss, and in severe cases hardware failure, software crashes, and interrupted operation across precision instruments. That symptom pattern strongly points to a site where both harmonic distortion and phase imbalance are impacting sensitive, digital-controlled systems in real work scenarios.

Power quality characteristics in R&D/testing facilities

-

Harmonic-rich nonlinear loads

Power supplies, servo drives, inverters, laboratory equipment, chargers, and power electronics test benches can generate harmonic currents that distort the voltage seen by other devices. In practice, this often correlates with “mysterious” malfunctions in sensitive equipment—especially when multiple devices share the same feeders. -

Three-phase current imbalance

R&D campuses often expand area-by-area. As single-phase and unevenly distributed loads accumulate, phase loading becomes asymmetric. This can drive neutral current increase, abnormal heating, and instability for equipment expecting balanced three-phase conditions. -

Fast-changing reactive power demand

Test rigs and large electromechanical systems switch states frequently. That creates rapid swings in reactive power and power factor—conditions that conventional static solutions struggle to follow, especially when the site runs a mix of precision electronics and heavy test equipment.

This project’s distinctive challenge was the concentration of sensitive precision instruments and high dependence on stable data and continuous operation. That means the cost of poor power quality isn’t limited to power loss—it shows up as false results, interrupted experiments, and equipment instability during critical R&D workflows.

What we delivered

To address both harmonic distortion and dynamic operating conditions—while controlling cost and footprint—the project adopted our Hybrid Dynamic Filter Compensation System, which integrates passive filtering/compensation and active filtering/dynamic compensation in one coordinated system.

Rather than treating “filtering” and “compensation” as separate projects, LSVG is designed to manage them as a single operational objective: stabilize the electrical environment that sensitive equipment depends on.

How LSVG matched the site’s power-quality problems

-

Hybrid architecture to handle “mixed reality” loads

The passive unit contributes power factor improvement and harmonic filtering, reducing the baseline burden. The active unit then dynamically targets what remains—suppressing harmonics and providing fast reactive compensation. This hybrid approach is well-suited to R&D/test environments where load composition shifts frequently and a purely active-only approach can be oversized. -

Dynamic, phase-by-phase control for unstable operating conditions

A single controller tracks load variation and adjusts reactive compensation range and harmonic filtering capacity, delivering phase-by-phase, stepless output of capacitive or inductive reactive current. That matters in facilities where imbalance and frequent state changes are part of daily operation. -

Wide harmonic coverage for real-world lab and power-electronics loads

The active unit supports filtering from the 2nd to the 51st order, and can dynamically allocate capacity between harmonic filtering and reactive compensation based on preset priorities—useful when different labs or test areas create different “dominant” issues at different times. -

Rapid response and compensation accuracy

The active unit’s bidirectional reactive current generation enables ultra-fast dynamic compensation that outpaces conventional thyristor switching behavior—helping stabilize power factor and reduce disturbances during test transitions. -

Industrial design + maintainability (built for facilities teams)

Modular passive unit design simplifies installation and maintenance and supports ventilation. The overall structure is compact with high efficiency and low self-consumption—important for engineering campuses with space and operational constraints. -

Monitoring designed for operational teams

Built-in HMI provides clear parameters, status visibility, and automatic fault diagnosis, with remote communication interfaces for real-time monitoring.

Results and Benefits

After deployment, the facility gained a cleaner and more stable electrical environment for precision work. Harmonics and imbalance-related hazards were reduced, improving the reliability of the power supply system and supporting the continuous, dependable operation of sensitive instruments and advanced electronic equipment. In practical terms, the value shows up as fewer test interruptions, more reliable data output, reduced unexpected equipment instability, and lower maintenance friction—all of which protect R&D throughput and project timelines.

Yout Trusted Power Quality Solutions Provider from China

Enhancing Your Efficiency with Industry-Leading Power Quality Solutions

When power quality is critical, customers look for more than a product—they look for a partner who’s done it many times before. In-Power Electric is one of China’s top three power quality solution providers, with 320+ IP rights (including 90+ invention patents and 50+ software copyrights) and participation in 50+ power quality standards. Our solutions have been deployed across industrial, commercial, infrastructure, and mission-critical environments, working alongside global brands, we help complex facilities achieve stable, compliant, and efficient power systems.

Let's talk about your project

Contact us to discuss your loads, harmonic profile, and reliability requirements. We’ll recommend a practical active filtering approach that fits your electrical system.