BOE B12 Gen-6 AMOLED line project: Industrial-Grade Reactive Power Management

- ndustry: Display manufacturing (Gen-6 flexible AMOLED)

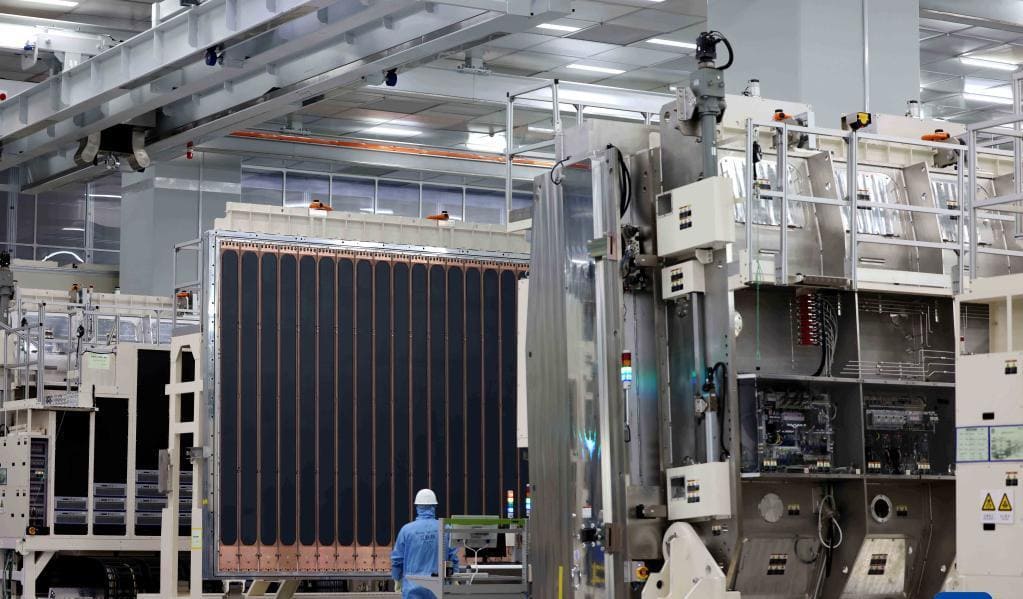

- Project: BOE Chongqing B12 6th-Gen Flexible AMOLED (flexible) line

- Facility scale: 970,000 m² total construction area · Building 1 approx. 523,000 m²

- Investment / capacity: RMB 46.5B total investment · 48,000 panels/month

- Solution delivered: 20,000+ kvar INPSVG Static Var Generators

Project Context:

BOE’s Chongqing B12 project is its third Gen-6 large-size flexible AMOLED production line, designed to supply high-generation flexible displays for smartphones, automotive applications, and foldable computing devices. With a total investment of RMB 46.5 billion, a planned monthly capacity of 48,000 panels, and a total construction area of 970,000 m², B12 represents a true “mega-fab” category. Building 1 alone—541 m × 219 m (about 523,000 m²)—was positioned as a world-leading AMOLED super factory as of late 2020.

In a facility of this scale, power quality is not a support function. It is part of the production system that determines whether precision equipment can operate continuously—and whether yield and throughput remain stable at mass-production levels.

Why power quality matters here — and what was at stake

Flexible AMOLED manufacturing is highly sensitive to process stability. The production line integrates large numbers of precision tools, automation systems, and power-electronic loads operating simultaneously across multiple process areas. Even small power instability can become a production risk.

For the operator, the consequences of poor power quality are severe and immediate:

-

Yield risk: Electrical instability can interrupt precision processing, increasing defect exposure and lowering yield.

-

Continuity risk: Unexpected trips, alarms, or tool interruptions can stop production sequences and trigger costly recovery steps.

-

Safety and system risk: Reactive power imbalance and power-quality stress can load the distribution system, creating hotspots and reliability hazards that threaten stable operation.

-

Cost risk: Reduced output stability shows up directly as higher manufacturing cost per panel and lower overall equipment effectiveness (OEE).

Electrical complexity of a Gen-6 flexible AMOLED line

The Gen-6 flexible AMOLED line is not a “steady load” factory. It is an environment where electrical conditions vary continuously across processes and production states.

Typical operating characteristics include:

-

Highly dynamic reactive power demand as process equipment cycles, automation stages shift, and utilities respond to thermal and airflow requirements.

-

Dense power-electronic loads across precision tools and facility systems, which increases sensitivity to voltage stability and power factor behavior.

-

Large-scale distribution footprint, where localized instability can propagate and affect upstream stability if not managed at the system level.

In practical terms: if reactive power and voltage stability are not controlled, the line becomes harder to run consistently at mass-production scale.

What we delivered

industrial-grade reactive power management at scale

We delivered a facility-level solution focused on one objective: keep the production power environment stable enough for precision tools to operate continuously and repeatably.

The deployed solution incorporated 20,000+ kvar of INPSVG Static Var Compensators, configured to match the line’s real operating behavior and the site’s distribution architecture. The solution was designed to:

-

Stabilize power factor and reactive power flow under changing production states, reducing the “swing” that puts stress on the network.

-

Support voltage stability so precision process tools can run with fewer power-related disturbances.

-

Reduce distribution-system loading and risk by improving reactive power balance and releasing capacity margin.

-

Protect production consistency at scale, ensuring reactive compensation performs reliably across a large, complex fab footprint rather than only at one operating point.

This is not a “single device” installation. It is system-level power conditioning engineered for a high-value production line.

Results and Benefits

With reactive power effectively controlled across the facility, BOE gained a more stable production power environment for long-duration, high-precision operation. The practical value is improved continuity and manufacturing consistency: fewer power-quality-driven disruptions, lower risk of instability affecting process performance, and stronger confidence in running the line at design throughput. By reducing the negative impact of power quality issues on the production line, the solution supports yield protection and improves manufacturing efficiency—exactly what mega-fabs require to operate profitably at scale.

Yout Trusted Power Quality Solutions Provider from China

Enhancing Your Efficiency with Industry-Leading Power Quality Solutions

When power quality is critical, customers look for more than a product—they look for a partner who’s done it many times before. In-Power Electric is one of China’s top three power quality solution providers, with 320+ IP rights (including 90+ invention patents and 50+ software copyrights) and participation in 50+ power quality standards. Our solutions have been deployed across industrial, commercial, infrastructure, and mission-critical environments, working alongside global brands, we help complex facilities achieve stable, compliant, and efficient power systems.

Let's talk about your project

Contact us to discuss your loads, harmonic profile, and reliability requirements. We’ll recommend a practical active filtering approach that fits your electrical system.