Low voltage

Static Var Generator

Step-less reactive power control in milliseconds for industrial LV systems

The Static Var Generator is engineered to deliver rapid and accurate reactive power compensation in low-voltage systems with dynamic load profiles. Leveraging an IGBT-based voltage source converter and high-speed digital control, the SVG responds within milliseconds to stabilize power factor and voltage. Its modular thermal design and fast protection logic support predictable behavior during both normal operation and grid disturbances, making it suitable for demanding industrial applications.

How It Works

Dynamic reactive power compensation based on VSC technology

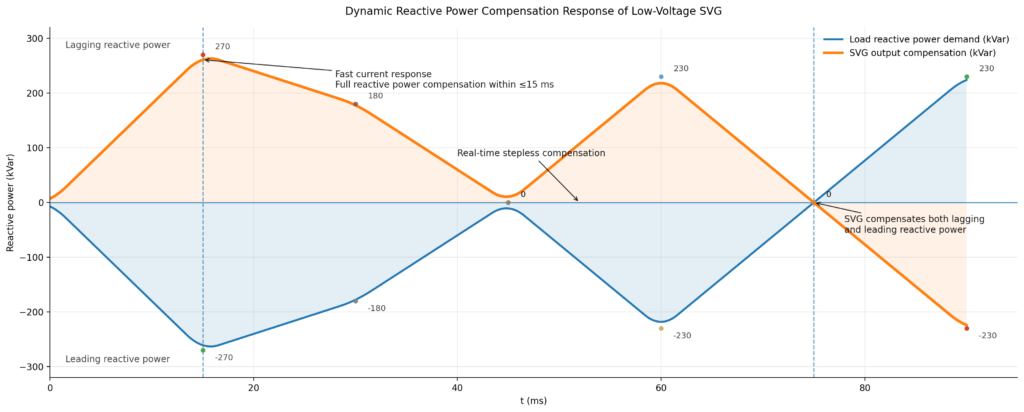

The Static Var Generator (SVG) uses an IGBT-based three-phase voltage source converter (VSC) to provide continuous and dynamic reactive power compensation. By controlling the amplitude and phase of the converter output voltage relative to the grid, the SVG injects or absorbs reactive power in real time.

This enables fast power factor correction and voltage stabilization under rapidly changing load conditions. Control parameters are configured according to site characteristics during commissioning, ensuring stable and predictable compensation performance in practical applications.

Solve the Power Quality Issues That Cost You Uptime

How SVG Addresses Power Quality Challenges

Real-Time Power Factor Correction

Continuously matches reactive output to load demand, holding PF at the setpoint without capacitor step delays or overshoot during fast changes.

Dynamic Voltage Support

Counters reactive spikes and drops quickly, reducing flicker and voltage variation that can affect PLCs, drives, and sensitive control circuits.

Harmonic Distortion Control

When harmonic function is used, compensates chosen harmonic orders to reduce distortion influence and improve current waveform behavior at the bus.

Three-Phase Load Balancing

Compensates phase reactive differences to reduce unbalance, easing stress on transformers and feeders while improving distribution symmetry.

Core Performance & Benefits

Why Choose Our Modular SVG?

Wide Voltage Tolerance

Operates on AC380 V ±20% and AC690 V ±20%, giving margin for utility variation and site drops without forcing redesign or frequent derating.

≤5 ms Dynamic Response

Delivers ≤5 ms response at 50 Hz/60 Hz, so compensation tracks fast load swings and keeps PF/voltage behavior stable during cycling processes.

Full-Range VAR Control

Provides PF control from -1 to +1, meaning it can absorb or supply VARs to avoid under-correction and leading PF overcompensation.

Multi-Objective PQ Modes

Reactive, unbalance, and harmonic modes can be combined and prioritized, so capacity is automatically allocated to the site’s current power-quality target.

Verified Harmonic Mitigation

Designed to address 2–25th odd harmonics (up to 95% stated filtering rate) when harmonic distortion must be managed alongside fast reactive power correction.

Integration + Scaling Ready

Supports unequal-capacity paralleling, 14 channels of discrete (dry-contact) control, and RS485 Modbus—reducing PLC/SCADA integration effort and easing phased expansion.

Technical Specifications (Low-Voltage SVG)

Category | Specification | Parameter |

|---|---|---|

Electrical Characteristics | Rated voltage | AC 380 V ±20% / AC 690 V ±20% |

Rated Frequency | 50 Hz/60 Hz ±5% | |

Single module capacity | 30 kvar / 50 kvar / 75 kvar / 100 kvar | |

Compensation Range | Power factor −1 to +1 | |

Dynamic response time | ≤ 5 ms | |

Efficiency | ≥ 97.5% | |

Functions & operating logic | Working modes | Reactive power compensation mode / three-phase unbalance mode / freely combinable |

Installation & expansion | Module installation method | Wall-mount / drawer type |

Multi-unit parallel operation | Supports multi-unit parallel; unequal-capacity parallel supported | |

Harmonic Performance | Harmonic compensation order | 2–25 odd harmonics |

Harmonic filtering rate | Up to 95% | |

Control & Communication | Passive control | Supports 14-channel passive control |

Communication | RS485; Modbus protocol | |

CT installation position | Source side / load side | |

Mechanical & Environmental | Cooling method | Forced air cooling |

Noise level | ≤ 55 dB | |

Protection rating | IP20 | |

Operating condition | Temperature: -25℃~55℃; RH max 95% (no condensation); altitude ≤3000m | |

Storage condition | Temperature: -45℃~55℃; RH max 95% (no condensation) |

Ready to Optimize Your Power Quality?

From measurement to commissioning, we help you turn power-quality requirements into an implementable design. Tell us your target power factor, voltage concerns, and load behavior. We’ll return a clear solution plan—configuration, control strategy, and expected improvement.