5G-enabled autonomous Electric commercial vehicle manufacturing base

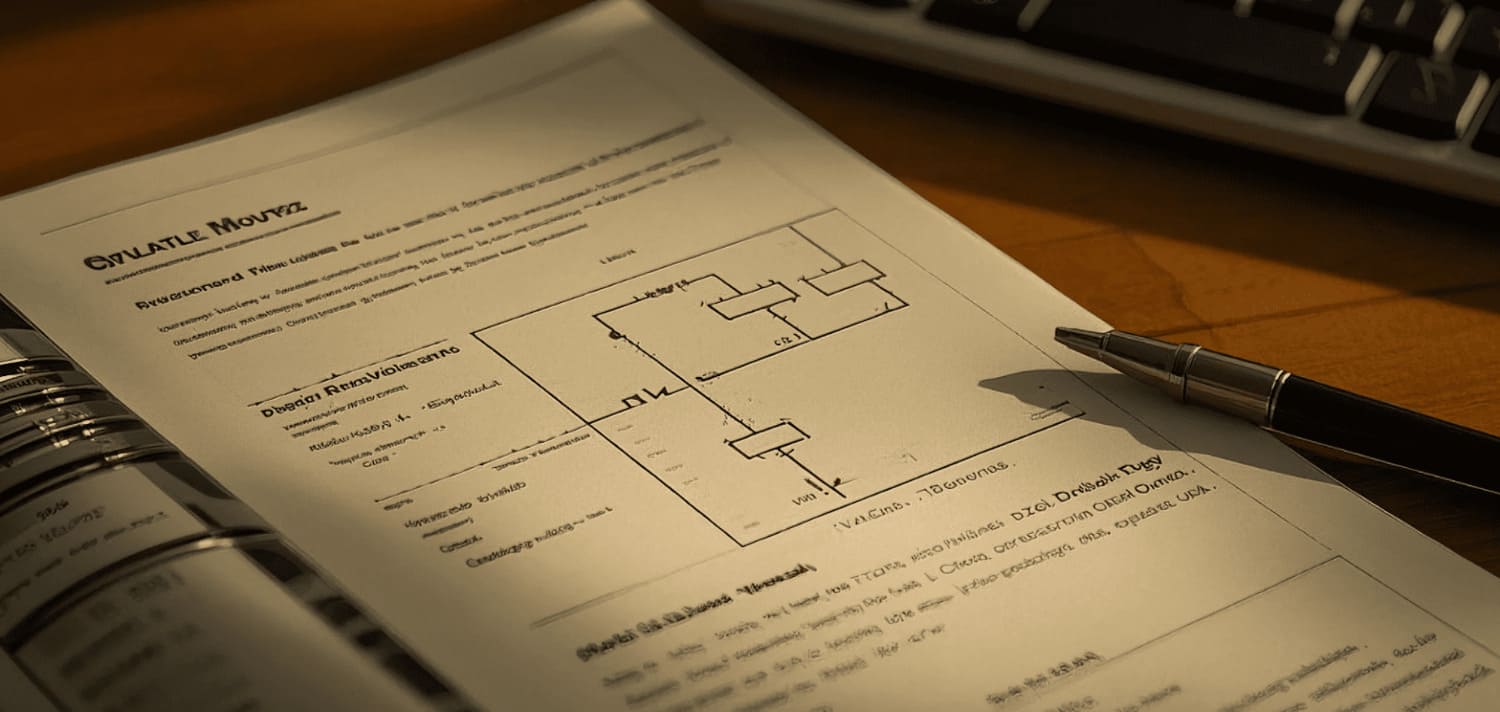

Dynamic VAR compensation + filtering to stabilize welding-heavy low-voltage power distribution

- Industry: Automotive manufacturing (high-end NEV)

- Facility: Beijing Benz Shunyi Plant (benchmarking Daimler “Factory 56”)

- Scale: ~1.06 million m² | Total investment RMB 11.9 billion

- Selected solution: Low-Voltage Dynamic Reactive Power Compensation and Filtering System

Project Context:

Shandong Haochi’s manufacturing base is recognized as China’s first 5G-enabled autonomous new-energy commercial vehicle manufacturing base and was listed as a key Shandong Province project (2020). The plant covers 32.7 hectares, includes stamping, welding, final assembly, battery assembly, core component production, R&D centers, utility power systems, and full plant infrastructure. Phase I is designed for 100,000 intelligent new-energy vehicles per year.

In this kind of high-throughput automotive facility, power quality is not a “facility detail.” It directly protects welding stability, line continuity, and distribution-system reliability—especially when the dominant loads are high-impact, fast-cycling welding machines.

Why power quality mattered here — and what was at stake

Automotive plants can tolerate many things; unstable low-voltage power is not one of them. In this project, the automotive welding lines are among the most demanding electrical loads in manufacturing. When large numbers of welders operate in cycles, the electrical system is exposed to rapid step changes and asymmetrical loading—the exact conditions that can push a distribution network into instability.:

-

Severe three-phase current imbalance: welding loads created strong phase asymmetry, tightening operating margin and increasing stress on upstream distribution assets.

-

Prominent low-order harmonic distortion: the system exhibited significant 3rd and 5th harmonics, consistent with rectifier/switching characteristics common in welding power supplies and related auxiliary equipment.

-

Fast-changing reactive demand: welding duty cycles cause reactive power to swing quickly, making traditional “slow” compensation ineffective.

-

Compounding system impacts: imbalance + harmonics together can amplify heating, increase nuisance protection events, and degrade power factor behavior—especially during high-load production windows.

This is exactly the scenario where “general reactive compensation” is not enough: unbalance requires phase-by-phase control, and harmonic stress must be addressed in the same solution logic.

What we delivered

Based on extensive automotive-sector engineering experience, the solution focus here was clear: stabilize the distribution system under unbalanced, harmonic-rich, fast-cycling welding loads. After multiple bidding rounds and technical evaluations, the project selected our Low-Voltage Dynamic Reactive Power Compensation & Filtering System (LSVG).

Instead of treating this as a generic compensation job, the system was applied as a targeted stabilization architecture:

-

Phase-by-phase dynamic compensation for three-phase unbalance

Because unbalanced welding loads cannot be corrected effectively with one-size-fits-all compensation, the system provides independent phase compensation to directly address current imbalance at its source behavior. -

Millisecond-level response without inrush current

The system uses fast thyristor zero-crossing switching to eliminate inrush current during switching events and respond on a millisecond scale—critical for welding cycles where reactive demand changes quickly. -

Filtering + compensation in one coordinated strategy

With significant 3rd and 5th harmonic presence, the solution is designed to improve the electrical environment while simultaneously stabilizing reactive behavior—reducing the “double-stress” effect that imbalance and harmonics can create together. -

Modular, compact, maintenance-friendly power unit

The core power unit adopts a modular design with compact structure, simple operation, easy installation, and convenient maintenance. The power unit is designed to be maintenance-free, which matters in plants where downtime windows are tight and reliability expectations are high.

Results and Benefits

With our dynamic compensation and filtering system in place, the plant gained a more stable distribution baseline under welding-driven load swings. In practical terms, this means reduced unbalance stress, fewer avoidable power-quality disturbances that can interrupt line rhythm, and a healthier electrical environment for long-term operation. The result is not just improved electrical metrics—it’s more predictable production continuity, lower maintenance friction, and stronger reliability margin in a facility designed for high-volume, high-intensity manufacturing.

Power Quality Solutions Proven in Automotive Manufacturing

Cleaner power for welding lines, press shops, and high-drive utility systems—without disrupting production.

Let's talk about your project

Contact us to discuss your loads, harmonic profile, and reliability requirements. We’ll recommend a practical active filtering approach that fits your electrical system.